AGM PVC Pipe fittings Raktherm PPR Plumbing Building material supplier in Karachi Lahore Islamabad Pakistan. Contact AR Corporation +92-322-3540656.

Tuesday, July 28, 2020

Tuesday, July 21, 2020

schedule 80 upvc pipes and fittings

Hydroplast Schedule 80 upvc

Contact +92-321-2248975

Hydroplast Schedule 80 UPVC (grey color) is one of the most broadly used thermoplastic Plumbing materials, common to many Installation applications.

Hydroplast UPVC is highly resistant to acids like alkali and alcohols as well as many other corrosive materials. The versatile range of options about jointing and other things that include solvent welding, threaded and mechanical connections make it ideal for easy, complain free installations.

Hydroplast Schedule-80 uPVC systems is light, tough and provide exceptional corrosion resistance for many applications with operating temperatures up to 59 degree celcius.

Monday, July 20, 2020

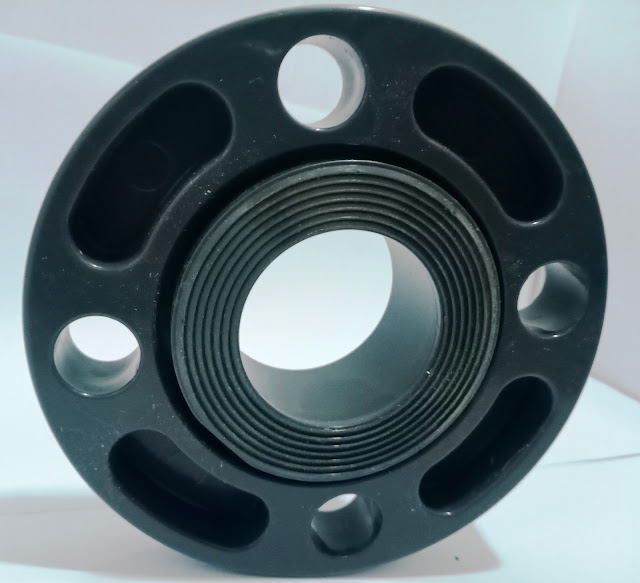

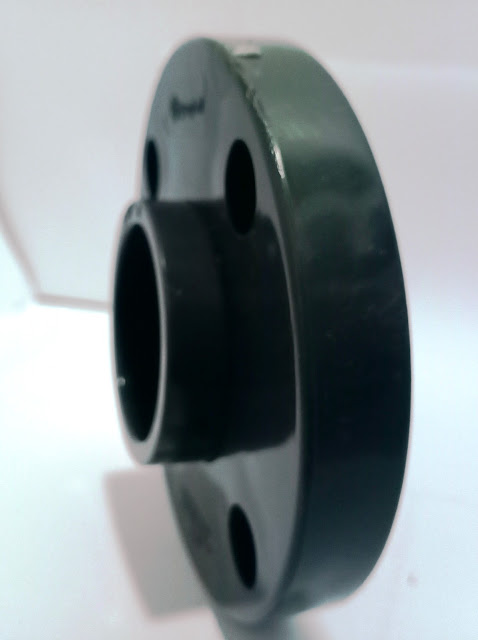

upvc flange schedule 80

Hydroplast

schedule 80 pvc flanges

Imported, stockist, distributor, dealers and suppliers in Karachi Pakistan.

Contact: +92-321-2248975

Butterfly valves suppliers in Karachi

HydroPlast Butterfly Valves

HydroPlast butterfly valves distributors, dealers, suppliers in Karachi Pakistan. Available in all specified sizes.

Contact: +92-321-2248975

Schedule 80 Ball Valve suppliers

Hydroplast

Ball valve schedule 80, high pressure in dark grey color, supppliers, distributors in Karachi Pakistan.

Contact: +92-321-2248975

schedule 80 pipes and fittings in Pakistan

Hydroplast Pakistan

Contact +92-321-2248975

Industrial thermoplastic piping systems are now firmly established in a wide range of applications since their introduction over forty years ago. The intervening years have seen dramatic growth in the choice of piping materials, diversity of products, dimensions available and the development of manufacturing standards.

Today there is an enormous choice for the designer faced with the task of selecting the optimum piping system for a specific application. Factors such as corrosion resistance, thermal characteristics, installation technique and life expectancy are all essential criteria that require consideration during the early stages of planning the piping system.

The aim of this part of our website is to raise the awareness amongst consultants, designers, engineers, and installers of the features and benefits of industrial thermoplastic piping systems. Here you will find an introduction to the properties of the different piping materials, their respective installation techniques, pressure and temperature limits, and corrosion and chemical resistance performance.

schedule 80 fittings suppliers in karachi Pakistan

Hydroplast

Contact +92-321-2248975

Materials (property) Chemical resistance Weathering resistance (Electrical) characteristics and Physiological , UPVC piping systems are produced w/o plasticizers and fillers, However for injection moulding purposes lubricants are added to assist in process of production of complex parts, and to combat the effects like Ultra Violet light, stabilisers are added. UPVC is produced by the polymerisation of vinyl chloride, a gaseous monomer.

Technical products manufactured from PVC-U can have a monomer content of 0.1ppm, which is considerably less than the specified limits. Owing to the high chlorine content of PVC-U, it does not support combustion after removal of a flame, and thus PVC-U falls into the class V-0 according to UL94.

Monday, June 22, 2020

Sunday, June 21, 2020

Thursday, June 18, 2020

RAKtherm pprc

raktherm pprc imported from UAE

Range : 20mm to 110mm complete pipe and fittings with aluminium stabi pipe

Call ; 0322-3540656 , 0300-2856741 , 0333-3645773

Email : arcorporations@gmail.com

Visit : www.arcorporation.pk

Wednesday, June 17, 2020

AGM UPVC pipe

Call : 0322-3540656 , 0300-2856741, 0333-3645773

Email : arcorporations@gmail.com

Visit : www.arcorporation.pk

Email : arcorporations@gmail.com

Visit : www.arcorporation.pk

Tuesday, April 7, 2020

PPRC pipe - Q-therm

pprc pipe

|

Q-therm

PPRC Piping System is an absolute solution for distribution application of hot & cold water in all modern residential apartments, commercial buildings, housing societies and various industries due to its high resistance to high temperature and pressure. Imported, 100% food grade German material is used in manufacturing of pipes & fittings. Q-therm pprc 20 mm to 110 mm complete pipe and fittings with aluminium pipes Call : 0322-3540656 , 0333-3645773 , 0300-2856741 Email : arcorporations@gmail.com Visit : www.arcorporation.pk |

Sunday, March 29, 2020

UPVC 4B SDR series

4B UPVC

UPVC PIPE Specifications

material : upvc (un plasticized polyvninyl chloride)

Max operating temperature 140 dgre.F or 60 dgre.c

Standards Listings : ASTM D-2241

SDR : series

COLOUR :white

Call : 0322-3540656 , 0333-3645773 , 0300-2856741

Email : arcorporations@gmail.com

Visit : www.arcorporation.pk

Sunday, March 22, 2020

upvc AGM SDR series

AGM upvc

Unplasticized Polyvinyl chloride (UPVC) is one of the most broadly used thermoplastic materials, common to many industries. UPVC is highly resistant to acids, alkalis, alcohols, and many other corrosive materials. AGM uses its own custom blend of UPVC compound to ensure that desirable physical properties are maintained with every production run.

AGM UPVC SDR is ideal for numerous applications when a standard ratio dimension is required. Pipes are available in white colors.

AGM SDR UPVC pipes can withstand temperatures up to 140°F (60°C).

AGM UPVC offers SDR Series sdr 41 , sdr 26 and sdr 32.5

Call : 0322-3540656 , 0300-2856741 , 0333-3645773

Email : arcorporations@gmail.com

Visit : www.arcorporation.pk

AGM UPVC offers SDR Series sdr 41 , sdr 26 and sdr 32.5

Call : 0322-3540656 , 0300-2856741 , 0333-3645773

Email : arcorporations@gmail.com

Visit : www.arcorporation.pk

Saturday, March 14, 2020

RAKtherm PPRC PIPE JOINING METHODS

RAKtherm PPRC PIPE JOINING METHODS

The most important elements for the installation of plastic pipe manufacturers and consumers reliability , quality of materials used by a resource to the point of being healthy is also important. The Merge method used in pprc pipes, socket welding method is called. Supply socket method ; with the support of the welding machine, pprc pipe and fittings to each other is made through melting and bonding of the source method. Step-by-step;

- The pipe, the pipe in the direction perpendicular to the axis of the pipe with sharp shears will be private so only the cutting process is done properly.

- The welding machine at 260°C. It should be heated up.

- Pipes and fittings welding machine by keeping ittirili toward each other from the translator. (Refer to the following resource table by looking at the source and the cooling period)

- The Merge takes place immediately from the source machine to the pipe and fittings . During this process, without compromising the axis of the pipe and fittings must be combined. So, when you put the parts in contact they must be omitted. Precautions against errors which will be held during the application process should be taken very carefully. Otherwise it is likely that the loss of gaps between pipes and fittings and giving rise to a homogeneous structure. Now this give information about the measures that must be considered and taken;

Pipe should be cutted with a pipe cutter and pipe segment in the direction perpendicular to the axis.

- Foiled foil for pprc pipe welding should be peeled while. After becoming made to the source of particles should be peeling foil pipes are not sure. The source of pprc pipe and fittings should not be contaminated.

- Source socket PPRC pipes 260 °C are carried out. The source of the source machine before the start of 260 °C. The heated, should be controlled.

- You should be careful with the source of standby time. In the melting process, while it is definitely not pipe and fittings should be returned.

- Parts bevel gear connections should not be used.

- After the flooring installation has finished, the sealing test should be performed.

Call ; 0322-3540656 , 0333-3645773 , 0300-2856741

Email : arcorporations@gmail.com

Visit : www.arcorporation.pk

- The welding machine at 260°C. It should be heated up.

- Pipes and fittings welding machine by keeping ittirili toward each other from the translator. (Refer to the following resource table by looking at the source and the cooling period)

- The Merge takes place immediately from the source machine to the pipe and fittings . During this process, without compromising the axis of the pipe and fittings must be combined. So, when you put the parts in contact they must be omitted. Precautions against errors which will be held during the application process should be taken very carefully. Otherwise it is likely that the loss of gaps between pipes and fittings and giving rise to a homogeneous structure. Now this give information about the measures that must be considered and taken;

Pipe should be cutted with a pipe cutter and pipe segment in the direction perpendicular to the axis.

- Foiled foil for pprc pipe welding should be peeled while. After becoming made to the source of particles should be peeling foil pipes are not sure. The source of pprc pipe and fittings should not be contaminated.

- Source socket PPRC pipes 260 °C are carried out. The source of the source machine before the start of 260 °C. The heated, should be controlled.

- You should be careful with the source of standby time. In the melting process, while it is definitely not pipe and fittings should be returned.

- Parts bevel gear connections should not be used.

- After the flooring installation has finished, the sealing test should be performed.

Call ; 0322-3540656 , 0333-3645773 , 0300-2856741

Email : arcorporations@gmail.com

Visit : www.arcorporation.pk

Wednesday, January 22, 2020

4B UPVC PIPES

4B UPVC

4B UPVCWater-supply Pipe Application Fields:

1. Food industry water supply system.

2. Urban water supply system.

3. Garden Irrigation, dig a well and other industrial pipe system.

4. Civil & industrial buildings' indoor water supply and intermediate water system.

5. Sea farming.

6. Water treatment plants.

7. Underground water supply system of residential quarter and plant area.

8. Ore Sand & Silt Pipeline Transport.

8. Ore Sand & Silt Pipeline Transport.

4B UPVC Water-supply Pipe Main Advantages:

1. Excellent physical and chemical properties: high impact strength, good pressure resistance , long service life (according to the national Ministry of Construction test data that the use of years 40-50)

2. Light weight: easy installation, the use of line and socket. Weight only one-seventh of the same diameter cast iron pipe, can greatly speed up the progress of the project and reduce construction costs.

3. Small fluid resistance: smooth inner wall, the rough coefficient of only 0.009, so the fluid resistance is small, compared with the same diameter cast iron pipe flow increased by 30%.

4. Anti-aging: the use of special compound design, no aging discoloration of the worry.

5. Pest control: the use of a unique auxiliary agent, so that the product will not issue psoriasis like the smell, to avoid termites, insects gnawing damage.

6. Non-toxic: not contain toxic lead salt and other toxic chemicals.

7. Save construction costs: lower integrated cost than the same specifications of the cast iron pipe, lower maintenance costs.

8. Longevity: more than 50 years under normal conditions.

Call : 0322-3540656 , 0333-3645773 , 0300-2856741

Email : arcorporations@gmail.com

Visit : www.arcorporation.pk

Email : arcorporations@gmail.com

Visit : www.arcorporation.pk

Monday, January 20, 2020

PPRC PN 20

RAKtherm pprc

Potable cold & hot water supply, indoor installations & central heating systems.

Thickness of Sizes according to Outer Diameter sizes. PN 20

20mm Diameter: 3.4mm Thickness

25mm Diameter: 4.2mm Thickness

32mm Diameter: 5.4mm Thickness

40mm Diameter: 6.7mm Thickness

50mm Diameter: 8.3mm Thickness

63mm Diameter: 10.5mm Thickness

75mm Diameter: 12.5mm Thickness

90mm Diameter: 15.0mm Thickness

110mm Diameter: 18.3mm Thickness

110mm Diameter: 18.3mm Thickness

Call :0322-3540656 , 0333-3645773 , 0300-2856741

Email : arcorporations@gmail.com

Visit : www.arcorporation.pk

Email : arcorporations@gmail.com

Visit : www.arcorporation.pk

Friday, January 17, 2020

PPRC Q-THERM

Q-therm pprc

PPRC polypropylene random Copolimer stands for , can provide very high performance even under high and low temperatures and pressure conditions. Heating and hot water systems used in fresh water polypropylene random copolymer (pprc) pipes ultra-high molecular structure due to a high level of use and durability. Raw material are manufactured from polypropylene random Copolimer. Plastic pipe, PPRC pipes in factories to human health, considering the value they give does not contain carcinogenic substances that affect human health, Europe''s leading countries and no successful results were obtained in tests it was determined that it did not cause health problems. In the United States, is approved by the health care law. Due to having a high tensile PPRC definitely does not affect the chemical properties of fluids in pipes. Algae pprc pipes DIN 8077 DIN 8078 landed the absence of standards and a minimum of pressure drops are manufactured.

Call : 0322-3540656 , 0333-3645773 , 03002856741

Email : arcorporations@gmail.com

Visit : www.arcorporation.pk

PPRC polypropylene random Copolimer stands for , can provide very high performance even under high and low temperatures and pressure conditions. Heating and hot water systems used in fresh water polypropylene random copolymer (pprc) pipes ultra-high molecular structure due to a high level of use and durability. Raw material are manufactured from polypropylene random Copolimer. Plastic pipe, PPRC pipes in factories to human health, considering the value they give does not contain carcinogenic substances that affect human health, Europe''s leading countries and no successful results were obtained in tests it was determined that it did not cause health problems. In the United States, is approved by the health care law. Due to having a high tensile PPRC definitely does not affect the chemical properties of fluids in pipes. Algae pprc pipes DIN 8077 DIN 8078 landed the absence of standards and a minimum of pressure drops are manufactured.

Call : 0322-3540656 , 0333-3645773 , 03002856741

Email : arcorporations@gmail.com

Visit : www.arcorporation.pk

GM PPRC

GM PPRCGM PPRC pipes and fittings are made of high molecular weight Polypropylene Random copolymer suitably stabilized for high temperature applications and especially with high environmental stress cracking resistance that enables long service life.

GM PPRC pipes and fittings are manufactured in accordance with German DIN standards,

This Raw material is recommended for manufacturing high pressure pipe lines.

- Clean & Contaminant – free air.

- Easy to install and simple to extend.

- Leak proof piping system.

- Corrosion resistance.

- Very less in Coefficient of friction

- Prevents high pressure loss.

- Allows higher flow rate.

- Zero condensate swan neck fitting.

- Light weight.

- Easy alteration flexibility.

- Easy dismantling and reusage.

- Connectors are brass with nickel coated

Call : 0322-3540656 , 0333-3645773 , 0300-2856741

Email : arcorporations@gmail.com

Subscribe to:

Comments (Atom)